|

SMARTech n. |

Integrated municipal WWTP |

Key enabling process(es) |

SMART-product(s) |

|

SMARTech4b |

Psyttalia (Greece) |

Sidestream SCENA+enhanced AD |

P-rich sludge |

Psyttalia Wastewater Treatment Plant (WWTP) is the largest wastewater treatment plant in Greece that serves the Greater Athens Area with a population of approximately 3.5 million people. Operation of Psyttalia WWTP commissioned in 1994 providing preliminary and primary treatment. In August 2004 with the completion of Phase B, Psyttalia WWTP was upgraded to provide full biological treatment to approximately 1,000,000 m3/d average dry weather flow. At Psyttalia WWTP, sludge treatment includes thickening by gravity thickeners for primary sludge and by belt thickeners for waste activated sludge, followed by anaerobic digestion (anaerobic, mesophilic, high-rate) for the thickened sludge mixture, digested sludge dewatering in centrifugal decanters and eventually dewatered sludge thermal drying in rotating drums. During 2016, a thermal hydrolysis process was installed to thermally hydrolize 50% of the total waste activated sludge produced daily. Following construction of the thermal hydrolysis process half of the total sludge produced is anaerobically digested and dewatered independently of the other half which follows conventional digestion and dewatering.

The separate treatment of sludge reject water relieves the wastewater line from nutrient loads and can result in attaining more stringent effluent standards with respect to nutrients. In the framework of the H2020 SMART-PLANT project, a novel process is applied at pilot scale for the separate treatment of sludge reject water of Psyttalia plant. The biological oxidation of nitrite into nitrate is by-passed by direct denitritation of nitrite. The process achieves high nutrient removal efficiency at a much lower energy and carbon footprint compared to conventional biological nutrient removal processes.

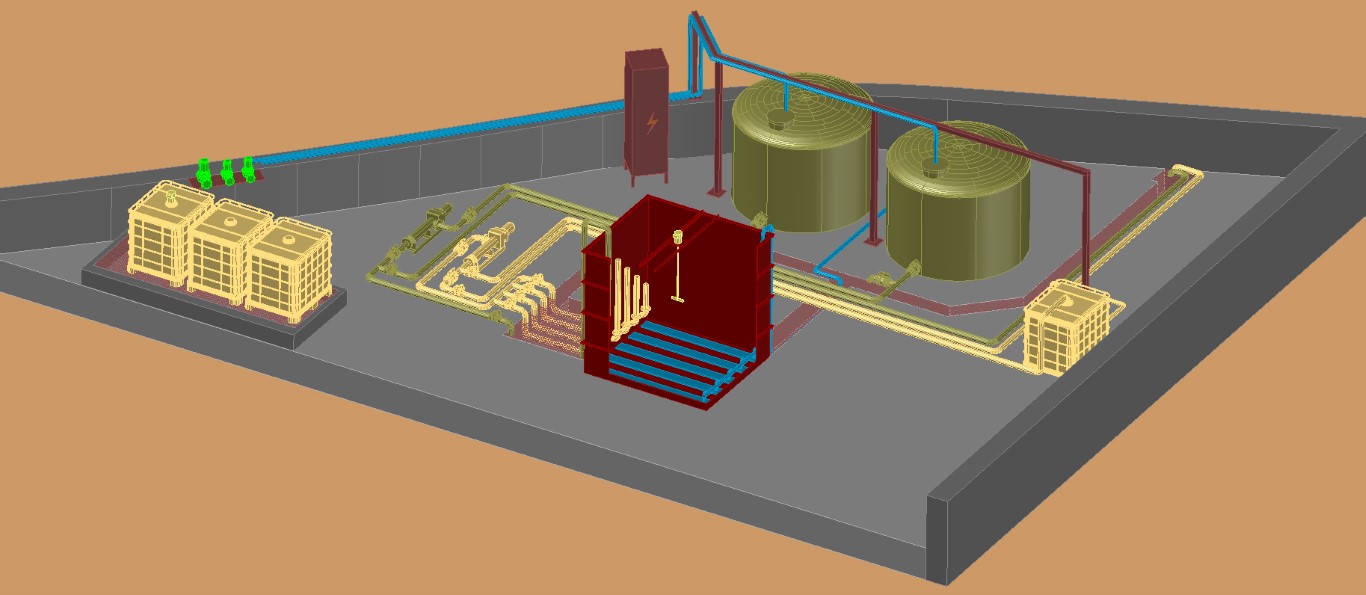

SMARTech4b is the key to enable the integration of the enhanced biogas recovery (by thermal hydrolysis) of sewage sludge with sidestream energy-efficient and compact nitrogen removal and phosphorus recovery. It modifies the original SCENA concept to treat the sludge reject water. The thermal hydrolysis process has been installed to treat 50% of the produced sludge, before this is sent for anaerobic digestion (AD). The integration of CAMBI with anaerobic digestion produces, after dewatering, a reject water stream that has a very high ammonium nitrogen concentration (>1.2 gN/L). The SMARTech4b was a pilot scale system that was treating the reject water produced following dewatering of anaerobically digested sludge that consists of a mixture of thermal hydrolyzed WAS and gravity thickened primary sludge.

The SMARTech4b pilot scale system was tested and validated at WWTP Psyttalia and consisted of a Sequencing Batch Reactor (SBR) that was treating the reject water from the dewatering facilities to biologically remove N and P. In order to increase the biodegradable COD/N and COD/P ratios reject water from primary sludge gravity thickeners was used. Alternatively, sodium acetate was also employed to increase the readily biodegradable COD in the reject water in order to efficiently remove nitrogen through short-cut nitrification/denitrification and to accumulate phosphorus in sludge through enhanced biological P removal via denitritation or aerobically.

Highlights and main results

- The maximum NLR implemented during a steady-state period of operation was 0.50 kg N m-3 d-1

- High performance for ammonia and TN removal was achieved (>90% and >75% removals respectively)

- The pilot-scale unit operated even under not favorable conditions (under low temperatures of the mixed liquor ≺15oC, periods of limited sodium acetate availability, etc.) by decreasing the NLR to 0.25kg N m-3 d-1

Impact

- Significant technical advancement through the 2.5-year operation of SMARTech 4b

- Evaluation of an energy efficient treatment unit capable to treat thermally pre-treated sludge reject water under stable conditions

- SMARTech 4b continuously operated properly within the typical variability of the reject water in terms of NH4N and P from the THP-AD process

- A technical envelope with the best operation strategies under different conditions has been defined and evaluated

- An algorithm for the SBR operation, was developed and adjusted during the pilot’s operation to optimize its performance