|

SMARTech n. |

Integrated municipal WWTP |

Key enabling process(es) |

SMART-product(s) |

|

Downstream SMARTechA |

London (UK) |

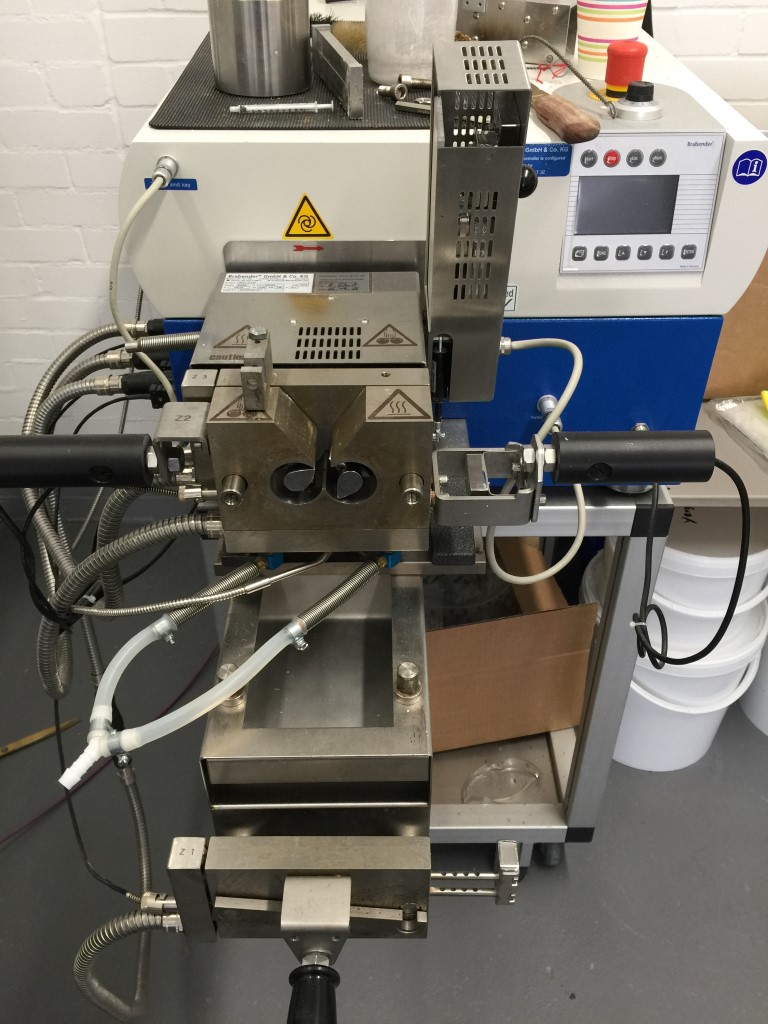

Formulation of recovered cellulosic and PHA materials+extrusion |

Biocomposite (Sludge Plastic Composite – SPC) |

|

SMARTech no: |

Downstream SMARTechA |

|

Objectives: |

- To enable the volume-utilisation of the recovered PHA bioplastics and cellulosic materials through the development of SMART-Plant sludge plastic composites (SPC) - To test and validate the continuous production of SPC |

|

Challenges: |

- Incompatibility between hydrophobic biopolymer and hydrophilic sludge cellulose - Homogeneity, uniformity and mechanical strength of the composites - Handling of materials, including material feeding and drying during processing - Potential redesign of screw geometry - Potential health and safety issues of new materials - Identification of uses of final product, which could be heavily influenced by visual appearance and mechanical properties - Product long term stability - Market research - Recyclability studies |

|

Integration within WWTP: |

The value-added post-processing technologies for and products from recovered WWTP resources enhance the efficiency of the existing WWTPs |

|

Key enabling process(es): |

- Surface modification of raw materials - Optimization of formulation and processing parameters - Feeding equipment and dosing system - Drying process of sludge cellulose - New design and manufacturing of screws - Extraction system |

|

SMART-product(s):

|

Solid and Hollow SPC |

|

Partners involved: |

1. UBRUN 2. ECODEK 3. UNIVR 4. CirTec |

DESCRIPTION:

SMART-Plant sludge plastic composite (SPC) is an entirely new concept beyond the existing wood plastic composite (WPC). SPC is developed using recycled sludge cellulose and PHA biopolymers with special design formulations. SMART-Plant SPC was scaled up with a continuous extrusion in an existing WPC production line. SPC was comparable to the conventional WPC and suitable for building and other industrial applications, while its production considerably consumes the recovered cellulose and delivers novel value added composite materials.

IMPACT:

The success of SMART-Plant SPC production proliferates the downstream processing industry with a value of > € 500 million, thus reduce the dependence on foreign feedstock sources and increase the competitiveness of European construction sector.