|

SMARTech n: 5 |

Sidestream Short-Cut Enhanced Phosphorus and PHA recovery (SCEPPHAR) |

|

Objectives: |

Recovery of PHA and struvite during the treatment of anaerobic supernatant via-nitrite |

|

Challenges: |

To enable the integration of conventional biogas recovery from cellulosic primary sludge with the energy-efficient nitrogen removal via-nitrite from sludge reject water and the recovery of PHA and struvite |

|

Integration within WWTP: |

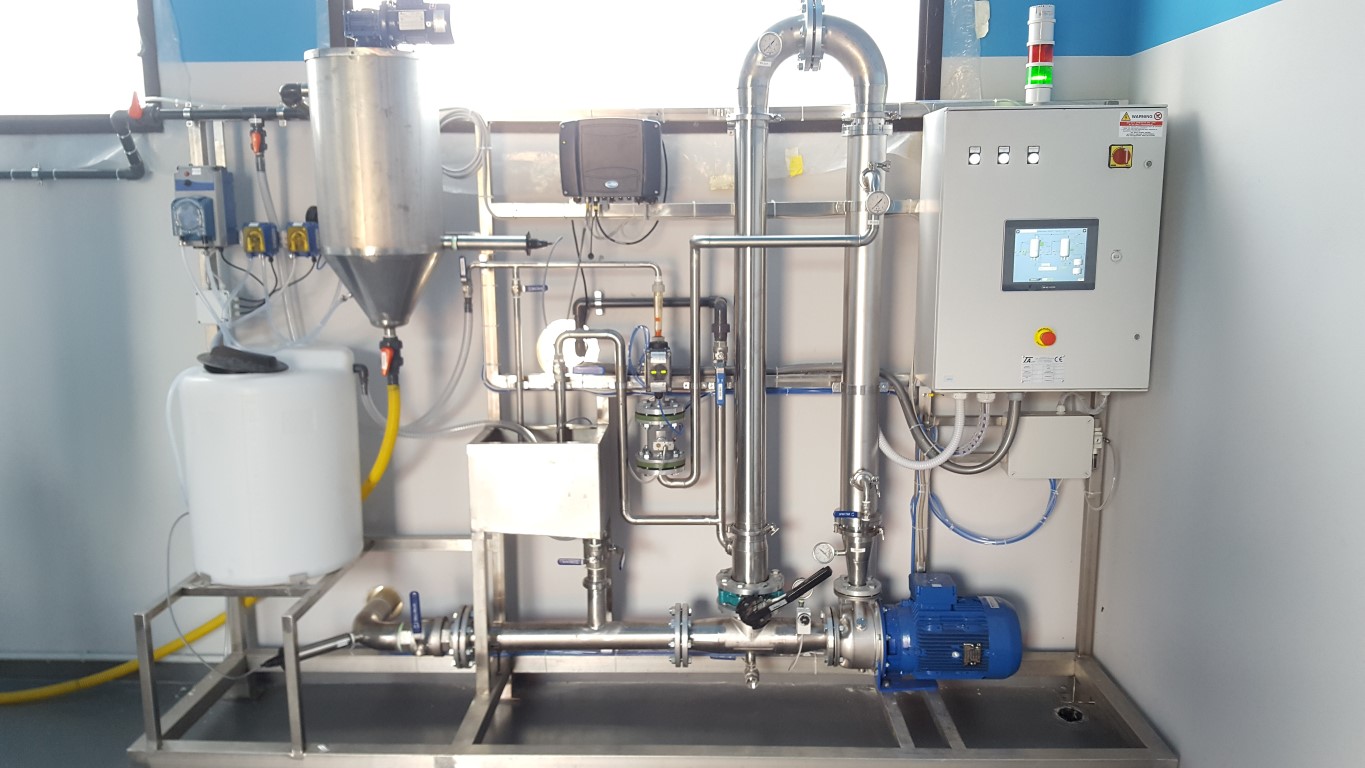

Smartech 5 is implemented in the sidestream of the anarobic digester of Carbonera WWTP |

|

Key enabling process(es): |

Biotechnology |

|

SMART-product(s):

|

PHA and Struvite |

|

Partners involved: |

1. UNIVR (main responsible of the Smartech) 2. ATS (owner of the Carbonera WWTP) 3. SALSNES (provider of the Rotating Belt Filter for the sieving of wastewater) 4. UR (characterization of the produced PHA) 5. BIOTREND (extraction of PHA from PHA enriched sludge) 6. UBRUN (post-processing of the extracted PHA for biocomposite applications) 7. Università Politecnica delle Marche (Coordinator of Smart-Plant Project) |

DESCRIPTION:

SMARTech 5 applies the SCEPPHAR concept, which was conceived as a modified version of SCENA for WWTPs larger than 150 kPE, where PHA recovery is an economically sustainable option. It accounts of the following subprocesses: (i) cellulosic primary sludge fermentation to enhance the production of VFAs and release nitrogen and phosphorus in soluble forms (ammonia and phosphate); (ii) solid and liquid separation of the fermentation products and recovery of struvite form the sewage sludge fermentation liquid by the addition of Mg(OH)2 to favour the precipitation; (iii) ammonium conversion to nitrite accomplished in a SBR; (iv) selection of PHA storing biomass in a SBR by the alternation of aerobic feast conditions and followed by anoxic famine conditions for denitritation driven by internally stored PHA as carbon source; (v) PHA accumulation using a fed-batch reactor to maximize the cellular PHA content of the biomass harvested from the selection stage.

IMPACT:

The pilot-scale system, that was tested and validated at WWTP Carbonera (Treviso, Italy), allowed the recovery of 0.7-0.8 kgPHA/day and 300 g/day of P precipitated salts and electrical energy savings of 15-25% for the treatment of the sludge reject water.