|

SMARTech n: |

Downstream SMARTech B |

|

Objectives: |

Valorisation of sludge and other sub-products generated in mainstream wastewater plants of the project developing optimized technologies for composting and biodrying of low porosity materials. |

|

Challenges: |

Optimizing the efficiency of the composting process of sludge (low porosity/high density wastes) to obtain high-quality compost (according the Fertilizer Directive Regulation (EC) No 2003/2003) requires the identification and availability of an adequate bulking agent. The process efficiency optimization depends also of an advanced airflow control system to guarantee aerobic adequate process conditions and the energy requirements. Biodrying process of sludge and other low porosity wastes is not widely applied due to their energy requirements. The development of an efficient technology will allow transforming these wastes to achieve valuable biomass fuel. |

|

Integration within WWTP: |

Material valorization of organic solid wastes generated in purge of the bioreactors of the WWTP and recycling other solid materials generated with high-nutrient content. Downstream SMARTech. B will be implemented at Manresa WWTP. |

|

Key enabling process(es): |

Biotechnology. Airflow control system. |

|

SMART-product(s):

|

High-quality compost was be produced through the composting of P-sludge mixed, with high-nutrient mesolites content that will be the bulking agent. Cellulosic sludge was be transformed in a biomass fuel under an optimized and efficient biodrying process. |

|

Partners involved: |

1. Cirtec BV (SMARTech 1) 2. Crandfield University – CU (SMARTech 3) 3. Università degli Studi di Verona - UNIVR (SMARTech 4a) |

DESCRIPTION:

The Downstream SMARTech B was testing and optimized two different biological treatments: (i) composting of nutrient-rich sludge together with zeolites, and (ii) biodrying of cellulosic sludge. Two pilot scale reactors were designed, build, started-up and validated to test and to optimize both processes. Minerals content of zeolites were used as additives in the composting process in order to improve the air-filled porosity of the material and the final properties of the compost according to the European Legislation (European Ecolabel to growing media (COM Decision (EC) 64/2007), Fertilizer Regulation (EC) No 2003/2003 and Soil Improvers (COM Decision (EC) 799/2006)). Biodrying of cellulosic sludge was undertaken to produce a high-quality biomass fuel under low energy requirements to obtain a final product with high calorimetric potential.

IMPACT:

The application of efficiency technologies of biodrying and composting to treat the sludge generated in WWTP permits to close the cycle of matter and to incorporate the circular economy concept in these facilities, providing the most appropriate system according to the local necessities.

These Downstream SmarTech allows to obtain high-category compost (at least, Rottegrade IV or maximum DRI 25 mmol O2·kg-1organic matter·h-1). Biodried cellulosic sludge achieved Lower Calorific Values higher than 4,700 cal·g-1

|

SMARTech n. |

Integrated municipal WWTP |

Key enabling process(es) |

SMART-product(s) |

|

Downstream SMARTechA |

London (UK) |

Formulation of recovered cellulosic and PHA materials+extrusion |

Biocomposite (Sludge Plastic Composite – SPC) |

|

SMARTech no: |

Downstream SMARTechA |

|

Objectives: |

- To enable the volume-utilisation of the recovered PHA bioplastics and cellulosic materials through the development of SMART-Plant sludge plastic composites (SPC) - To test and validate the continuous production of SPC |

|

Challenges: |

- Incompatibility between hydrophobic biopolymer and hydrophilic sludge cellulose - Homogeneity, uniformity and mechanical strength of the composites - Handling of materials, including material feeding and drying during processing - Potential redesign of screw geometry - Potential health and safety issues of new materials - Identification of uses of final product, which could be heavily influenced by visual appearance and mechanical properties - Product long term stability - Market research - Recyclability studies |

|

Integration within WWTP: |

The value-added post-processing technologies for and products from recovered WWTP resources enhance the efficiency of the existing WWTPs |

|

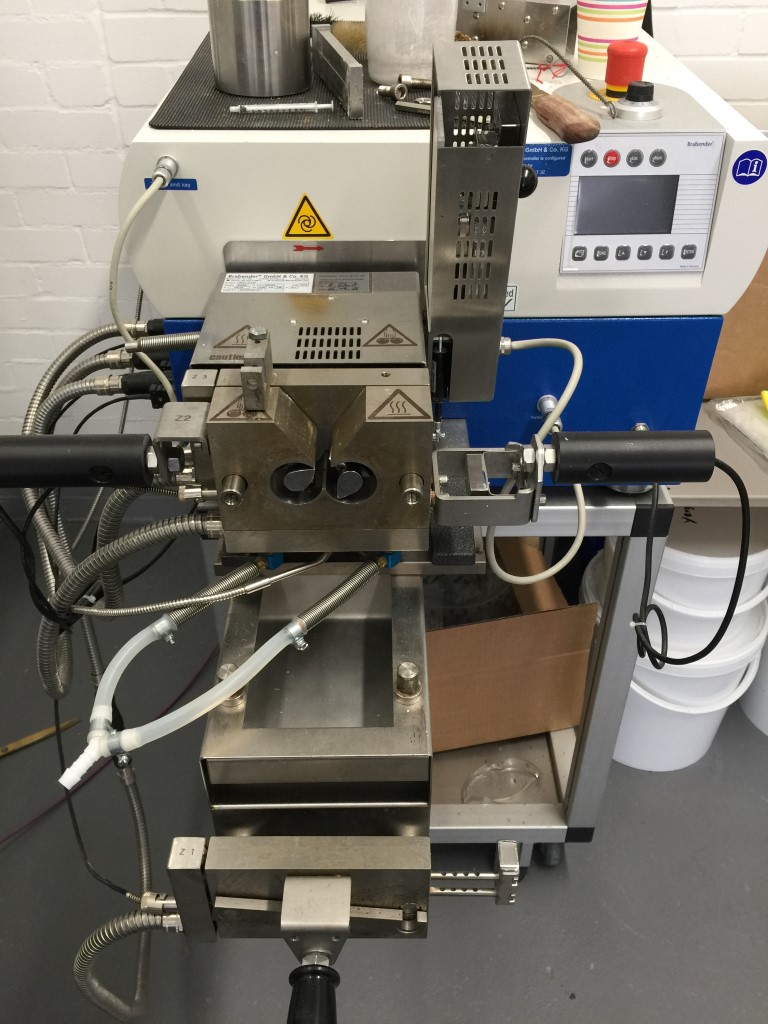

Key enabling process(es): |

- Surface modification of raw materials - Optimization of formulation and processing parameters - Feeding equipment and dosing system - Drying process of sludge cellulose - New design and manufacturing of screws - Extraction system |

|

SMART-product(s):

|

Solid and Hollow SPC |

|

Partners involved: |

1. UBRUN 2. ECODEK 3. UNIVR 4. CirTec |

DESCRIPTION:

SMART-Plant sludge plastic composite (SPC) is an entirely new concept beyond the existing wood plastic composite (WPC). SPC is developed using recycled sludge cellulose and PHA biopolymers with special design formulations. SMART-Plant SPC was scaled up with a continuous extrusion in an existing WPC production line. SPC was comparable to the conventional WPC and suitable for building and other industrial applications, while its production considerably consumes the recovered cellulose and delivers novel value added composite materials.

IMPACT:

The success of SMART-Plant SPC production proliferates the downstream processing industry with a value of > € 500 million, thus reduce the dependence on foreign feedstock sources and increase the competitiveness of European construction sector.

|

SMARTech n: 5 |

Sidestream Short-Cut Enhanced Phosphorus and PHA recovery (SCEPPHAR) |

|

Objectives: |

Recovery of PHA and struvite during the treatment of anaerobic supernatant via-nitrite |

|

Challenges: |

To enable the integration of conventional biogas recovery from cellulosic primary sludge with the energy-efficient nitrogen removal via-nitrite from sludge reject water and the recovery of PHA and struvite |

|

Integration within WWTP: |

Smartech 5 is implemented in the sidestream of the anarobic digester of Carbonera WWTP |

|

Key enabling process(es): |

Biotechnology |

|

SMART-product(s):

|

PHA and Struvite |

|

Partners involved: |

1. UNIVR (main responsible of the Smartech) 2. ATS (owner of the Carbonera WWTP) 3. SALSNES (provider of the Rotating Belt Filter for the sieving of wastewater) 4. UR (characterization of the produced PHA) 5. BIOTREND (extraction of PHA from PHA enriched sludge) 6. UBRUN (post-processing of the extracted PHA for biocomposite applications) 7. Università Politecnica delle Marche (Coordinator of Smart-Plant Project) |

DESCRIPTION:

SMARTech 5 applies the SCEPPHAR concept, which was conceived as a modified version of SCENA for WWTPs larger than 150 kPE, where PHA recovery is an economically sustainable option. It accounts of the following subprocesses: (i) cellulosic primary sludge fermentation to enhance the production of VFAs and release nitrogen and phosphorus in soluble forms (ammonia and phosphate); (ii) solid and liquid separation of the fermentation products and recovery of struvite form the sewage sludge fermentation liquid by the addition of Mg(OH)2 to favour the precipitation; (iii) ammonium conversion to nitrite accomplished in a SBR; (iv) selection of PHA storing biomass in a SBR by the alternation of aerobic feast conditions and followed by anoxic famine conditions for denitritation driven by internally stored PHA as carbon source; (v) PHA accumulation using a fed-batch reactor to maximize the cellular PHA content of the biomass harvested from the selection stage.

IMPACT:

The pilot-scale system, that was tested and validated at WWTP Carbonera (Treviso, Italy), allowed the recovery of 0.7-0.8 kgPHA/day and 300 g/day of P precipitated salts and electrical energy savings of 15-25% for the treatment of the sludge reject water.

|

SMARTech n. |

Integrated municipal WWTP |

Key enabling process(es) |

SMART-product(s) |

|

SMARTech4b |

Psyttalia (Greece) |

Sidestream SCENA+enhanced AD |

P-rich sludge |

Psyttalia Wastewater Treatment Plant (WWTP) is the largest wastewater treatment plant in Greece that serves the Greater Athens Area with a population of approximately 3.5 million people. Operation of Psyttalia WWTP commissioned in 1994 providing preliminary and primary treatment. In August 2004 with the completion of Phase B, Psyttalia WWTP was upgraded to provide full biological treatment to approximately 1,000,000 m3/d average dry weather flow. At Psyttalia WWTP, sludge treatment includes thickening by gravity thickeners for primary sludge and by belt thickeners for waste activated sludge, followed by anaerobic digestion (anaerobic, mesophilic, high-rate) for the thickened sludge mixture, digested sludge dewatering in centrifugal decanters and eventually dewatered sludge thermal drying in rotating drums. During 2016, a thermal hydrolysis process was installed to thermally hydrolize 50% of the total waste activated sludge produced daily. Following construction of the thermal hydrolysis process half of the total sludge produced is anaerobically digested and dewatered independently of the other half which follows conventional digestion and dewatering.

The separate treatment of sludge reject water relieves the wastewater line from nutrient loads and can result in attaining more stringent effluent standards with respect to nutrients. In the framework of the H2020 SMART-PLANT project, a novel process is applied at pilot scale for the separate treatment of sludge reject water of Psyttalia plant. The biological oxidation of nitrite into nitrate is by-passed by direct denitritation of nitrite. The process achieves high nutrient removal efficiency at a much lower energy and carbon footprint compared to conventional biological nutrient removal processes.

SMARTech4b is the key to enable the integration of the enhanced biogas recovery (by thermal hydrolysis) of sewage sludge with sidestream energy-efficient and compact nitrogen removal and phosphorus recovery. It modifies the original SCENA concept to treat the sludge reject water. The thermal hydrolysis process has been installed to treat 50% of the produced sludge, before this is sent for anaerobic digestion (AD). The integration of CAMBI with anaerobic digestion produces, after dewatering, a reject water stream that has a very high ammonium nitrogen concentration (>1.2 gN/L). The SMARTech4b was a pilot scale system that was treating the reject water produced following dewatering of anaerobically digested sludge that consists of a mixture of thermal hydrolyzed WAS and gravity thickened primary sludge.

The SMARTech4b pilot scale system was tested and validated at WWTP Psyttalia and consisted of a Sequencing Batch Reactor (SBR) that was treating the reject water from the dewatering facilities to biologically remove N and P. In order to increase the biodegradable COD/N and COD/P ratios reject water from primary sludge gravity thickeners was used. Alternatively, sodium acetate was also employed to increase the readily biodegradable COD in the reject water in order to efficiently remove nitrogen through short-cut nitrification/denitrification and to accumulate phosphorus in sludge through enhanced biological P removal via denitritation or aerobically.

Highlights and main results

- The maximum NLR implemented during a steady-state period of operation was 0.50 kg N m-3 d-1

- High performance for ammonia and TN removal was achieved (>90% and >75% removals respectively)

- The pilot-scale unit operated even under not favorable conditions (under low temperatures of the mixed liquor ≺15oC, periods of limited sodium acetate availability, etc.) by decreasing the NLR to 0.25kg N m-3 d-1

Impact

- Significant technical advancement through the 2.5-year operation of SMARTech 4b

- Evaluation of an energy efficient treatment unit capable to treat thermally pre-treated sludge reject water under stable conditions

- SMARTech 4b continuously operated properly within the typical variability of the reject water in terms of NH4N and P from the THP-AD process

- A technical envelope with the best operation strategies under different conditions has been defined and evaluated

- An algorithm for the SBR operation, was developed and adjusted during the pilot’s operation to optimize its performance

|

SMARTech n 4a: |

SCENA: Short-Cut Enhanced Nutrients Abatement |

|

Objectives: |

Biological nitrogen removal and P-bioaccumulation via-nitrite during the treatment of anaerobic supernatant |

|

Challenges: |

To enable the integration of conventional biogas recovery from sewage sludge with sidestream energy-efficient and compact nitrogen removal and phosphorus recovery. |

|

Integration within WWTP: |

Smartech 4a is implemented in the sidestream of the anarobic digester of Carbonera WWTP |

|

Key enabling process(es): |

Biotechnology |

|

SMART-product(s):

|

P-rich Sludge, VFA |

|

Partners involved: |

1. University of Verona 2. Alto Trevigiano Servizi SpA 3. SCAE Srl 4. Università Politecnica delle Marche |

DESCRIPTION:

SMARTech 4a applies the SCENA system which integrates the following processes: (o) optional upstream concentration of cellulosic sludge,(i) fermentation of dynamic thickened sewage sludge to produce VFAs as carbon source, and (ii) via nitrite nitrogen and phosphorus removal (by P-bioaccumulation) from sludge reject water using an SBR. In this configuration, nitrogen is removed through the bioprocesses of nitritation/denitritation, and Enhanced Biological Phosphorus removal (EBPR) via nitrite using the VFAs from sludge fermentation liquid as carbon source

IMPACT:

The full-scale demo application developed in the WWTP of Carbonera (Italy) was treating the total flowrate of reject water resulted from the dewatering of the anaerobic digestate (around 40-50 m3/day). Smartech 5 allowed the recovery of 7-8 kg P-rich sludge per capita per year and the electrical energy savings of 20-30% for the treatment of sludge reject water.

Highlights and main results

- Smartech 4a (SCENA) was validated under real enviromental conditions

- Average and phosphorus removal was 78-80%, operating at vNLR up to 0.7 kgN/m3 per day

- VFAs productivity was 0.9 kgCODVFA/capita per year, treating 25% of the sewage sludge

- P recovered as P rich sludge was 0.8-1.0 kg P rich sludge per capita per year

- ETV final report was delivered to RINA for the submission to the European portal

Impact

- ATS has already considered the scale-up of SMARTech 4a in the final project design of the Castelfranco “Sludge Centre”.

- Integration of SMARTech 4a in the sludge line of Sesto San Giovanni (SSG) and Robecco sul Naviglio (RSN) WWTPs, owned by the water utility CAP holding.

|

SMARTech n. |

Integrated municipal WWTP |

Key enabling process(es) |

SMART-product(s) |

|

SMARTech3 |

Cranfield (UK) |

Mainstream tertiary hybrid ion exchange |

Nutrients |

Cranfield WWTP treats domestic wastewater from the Cranfield University campus including offices, student accommodation halls, 2 hotels as well as street and airfield run-off. The influent flow is 675 m3/day (dry weather -2,840 Population equivalent). Wastewater treatment process includes primary and secondary treatment followed by filtration.

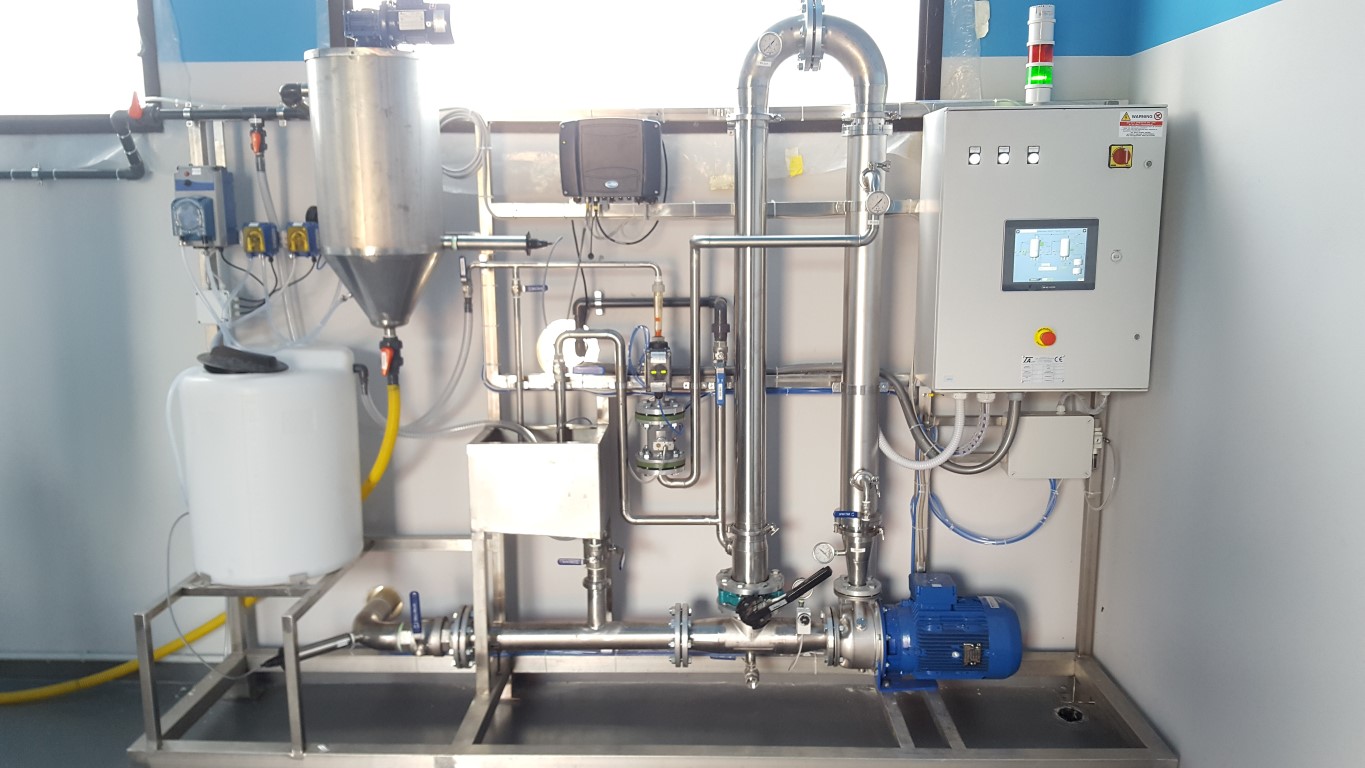

SMARTech3 is the key to enable tertiary recovery of N and P based fertilizer based on ion-exchange processes to remove and recover nutrients from secondary effluents. Two different ion exchange media applied which were able to successfully capture/remove ammonia and phosphate from the secondary effluent. To overcome the limited supply chain of the ion exchanging materials, new ion exchange media, manufactured in the UK, were applied. The aim was to optimize the regeneration cycles for the nutrient recovery, trying to maintain a high sorption capacity after each regeneration cycle.

The overall SMARTECH3 includes: 1 micro-screen filtration for secondary effluent solids removal, 1 ion exchange process for ammonia (N) removal with MesoLite media; 1 ion exchange process for phosphorus (P) removal with hybrid ion exchange media (HAIX) media, regenerant storage tanks (NaCl and NaOH), regenerant rinse water tanks and nutrient recovery processes: liquid-liquid membrane process for ammonia recovery, producing ammonium sulfate and a mixing tank and filter for phosphate recovery as calcium phosphate (hydroxyapatite).

SMARTech3 was operated as demonstration plant fed with 10m3/day of secondary effluent at the Cranfield University pilot-hall. The new system will be applied at the Cranfield municipal WWTP (UK) and will treat approximately 10-60 m3/d.

Highlights and main results

- Ion exchange processes can be used to remove and recover N and P from municipal wastewater, without start-up lag and min impact of temperature

- Multiple use and recovery of regenerants leading to an economic feasibility of the IEX technology in the wastewater industry

- Recovery of high purity products hydroxyapatite and ammonium sulphate

Impact of the system

- Reduction in energy of up to 38%

- Reduction in GHG emissions, estimated at 10-20%

- Significant reduction in footprint

- Recovered hydroxyapatite up to 3.4 tonne/year

- Recovered ammonium sulphate up to 98 tonne/year

|

SMARTech n. |

Integrated municipal WWTP |

Key enabling process(es) |

SMART-product(s) |

|

SMARTech2b |

Manresa (Spain) |

Mainstream SCEPPHAS |

P-rich sludge, PHA |

The municipal WWTP of Manresa (Barcelona, Spain) receives an average flow rate of 27,000 m3/ day. It consists of a pre-treatment (gross and grit removal), primary treatment with a clarifier and a secondary biological stage. There are two main treatment lines in the secondary stage; each one has three anoxic reactors (1,460 m3) and one aerobic reactor (6,782 m3). It uses a Modified Ludzack-Ettinger Process (MLE) for COD and N removal with conventional nitrification/denitrification. Air is bubbled from the bottom of the aerobic tanks with membrane diffusers. An internal recycle pipe connects the aerobic zone to the anoxic one to bring the nitrate to be denitrified in the anoxic zone. At the end of the secondary stage, two settlers separate the biomass from the treated effluent. Settled biomass returns to the entrance of the anoxic reactor by an Archimedes screw. Phosphorus is removed by chemical precipitation with FeCl3. The effluent, after leaving the secondary settler, can be chlorinated and it is disposed to the environment at the Cardener River, which is considered a sensitive area.

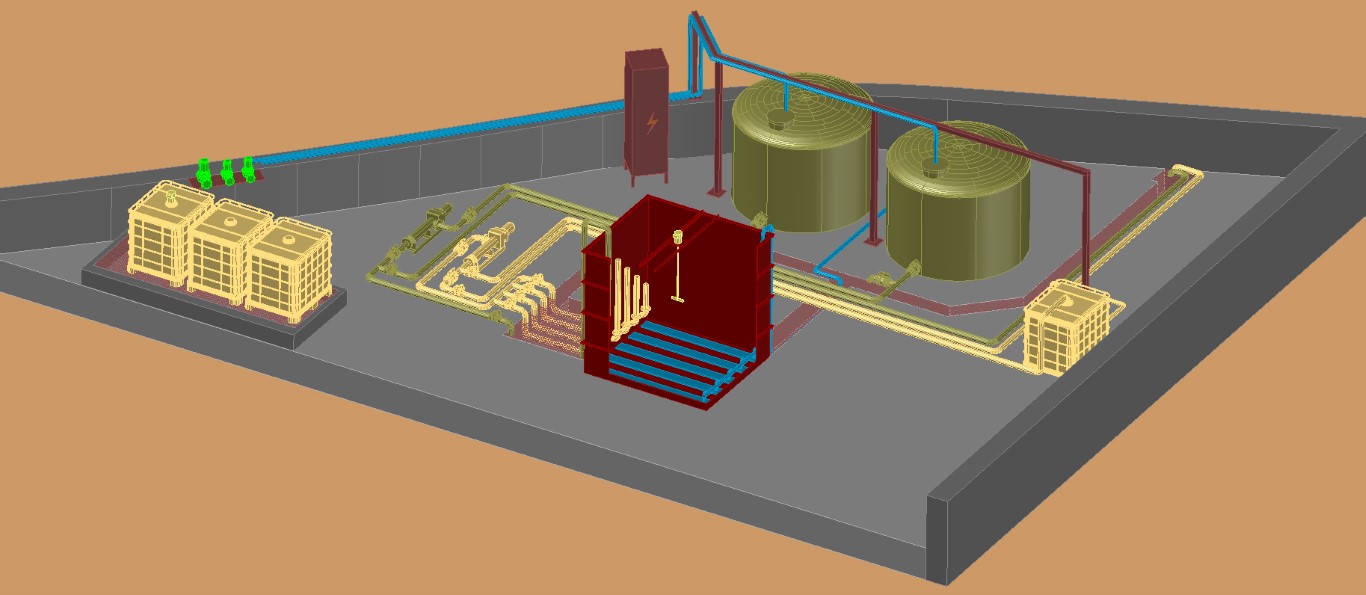

SMARTech2b is the key to enable secondary mainstream energy-efficient resource recovery. It applies the mainstream SCEPPHAR (Short - Cut Enhanced Phosphorus and PHA Recovery) and consists of two SBR; one for heterotrophic bacterial growth operated under anaerobic/anoxic/aerobic sequence (HET-SBR), and another SBR for autotrophic nitrifiers growth (AUT-SBR), an interchange vessel and a chemical system for P-recovery as struvite. The integrated system accomplishes enhanced N-removal and P-recovery in municipal WWTP. PHA was recovered from the anaerobic purge of the SBR. The liquid volume of each SBR vessel is 2500 L, for the interchange vessel is the same as for the SBR and for the struvite precipitation vessel is 400 L.

The pilot-scale system has a reaction volume of 6-8 m3 and was installed at the Manresa municipal WWTP (Spain) to treat about 10 m3/d of sewage in 3 cycles of 8 hours per day. The main objectives of the pilot- plant implemented as a mainstream treatment for municipal wastewater were to: (1) treat 10m3/d of wastewater after primary treatment; (2) achieve an effluent with P < 1 mg/L and TN <10 mg/L without addition of external carbon source nor FeCl3 for P precipitation; (3) remove N via nitrite with a removal up to 90%; (4) recover around 50% of P in the influent as struvite; (5) produce a waste sludge with PHA content up to 10%.

Highlights and main results

- First implementation at demo scale and under relevant conditions of the integration of i) shortcut nitrification, ii) P recovery and iii) production of sludge with increased PHA%

- Successful long-term operation of the mainstream SCEPPHAR at demo scale (7.8 m3)

- Removal efficiencies: TN: 86%, P: 93%, CODT: 79%

- Including nitrite shortcut did not affect C, N and P removal

- Average 45% of influent P was recovered as struvite (up to 63%)

- The highest PHA percentage in the biomass was 9.2%

Impact of the system

- EBPR can be combined with a high P recovery as struvite in a mainstream configuration

- Sludge generated contains a higher amount of PHA than conventional sludge

- Stable nitrogen via nitrite shortcut, without increasing N2O emissions (GHG)

- High COD, N and P removal are stably obtained if enough rbCOD is available in the wastewater

|

SMARTech n. |

Integrated municipal WWTP |

Key enabling process(es) |

SMART-product(s) |

|

SMARTech2a |

Karmiel (Israel) |

Mainstream polyurethane-based anaerobic biofilter |

Biogas, Energy-efficient water reuse |

The Karmiel WWTP was built in order to treat wastewater from Karmiel town and its region including wastewater originating form industrial areas. The WWTP was built by a co-partnership of equal shares (50% each) of the National Water Company “Mekorot” and the Regional Sewage Association. Wastewater is treated in a conventional activated sludge system, providing sludge treatment in thickeners, followed by anaerobic digestion and sludge dewatering.

AgRobics has developed an advanced anaerobic technology (AAT) for treating heterogeneous wastewater. The AAT is a “bio - stabilized”, polymer -based matrix impregnated with unique anaerobic microorganisms. The matrix has large surface area and high capacity that enables the loading of higher number of microorganisms compared to incumbent wastewater treatment methods. In addition, the matrix provides physical protection for the microorganisms.

SMARTech2a is the key to enable secondary biogas recovery from small-medium municipal WWTP where irregular organic-load peaks often occur. It applies a secondary anaerobic biofilter with an innovative polymeric based immobilization matrix to treat anaerobically sewage and produce biogas. The system results in high COD and TSS removal as well as biogas production, providing treated effluent adapted for reuse in agriculture or reclamation after post-treatment. The demo system had a reaction volume of 25 m3 and was installed at the municipal WWTP of Karmiel (Israel) to treat 100-120 m3/d of sewage.

Highlights and main results

- Increase the production of biogas by 15-25%

- Simple operation

- Low energy consumption

- Reduction of the organic load entering the biological stage of the WWTP and less energy costs for aeration (6-8% reduction of the total energy consumption)

- Reduction in the amount of biological sludge and the associated disposal costs (15-20% reduction)

- High process stability dealing with high contamination levels (e.g. solids, salts, fats, toxins and oils) and irregular organic loads

Impact of the system

- Increasing of the total biogas production by 20% (15-25%)

- Significant reduction of total sludge production ( ≺20% )

- Reduction in GHG emissions, if a degasifier is integrated estimated at 7%

- Reduction of the total energy demand by 6-8% in the warm period (March-November) and zero additional demand in the cold period (December-February) (5-6% reduction at annual basis)

|

SMARTech n. |

Integrated municipal WWTP |

Key enabling process(es) |

SMART-product(s) |

|

SMARTech1 |

Geestmerambacht (Netherlands) |

Upstream dynamic fine-screen and post-processing of cellulosic sludge |

Cellulosic sludge, refined clean cellulose |

The WWTP of Geestmerambacht is situated between Schoorldam and Koedijk, along the Noordholland Canal in the Dutch province North Holland, treating Dry Weather Flow (DWF), of 4,160 m3/h and maximum flow (FFT) of 16,300 m3/h. Anaerobic and aerobic treatment is provided for wastewater, while sludge treatment line includes the processes of thickening and dewatering.

SMARTech1 is the key to enable primary cellulose harvesting from medium-large WWTPs. It applies the primary concentration of wastewater by Salsnes Filter dynamic fine-sieve, which can enable maximal recovery of resources. The Salsnes Filter separates cellulosic sludge that is followed by post-processing inside the WWTP. The latter includes a compact sequence of operation unites imported by the paper and food industry to produce clean and marketable cellulose. The cellulosic material was also provided outside the WWTP for the downstream blending with PHA and processing for final bio-composite production (Downstream SMARTechA).

Highlights and main results

- Overall winner Aquatech Innovation Award 2017

- Recovery of 150 kg/week of recovered cellulose ReCell®

- ReCell® has been used as additive in road construction and as fibre material in bio-composites

- Reduction of CO2 emissions of 2 tonnes per ton ReCell®

Impact of the system

- Reduction in aeration energy of up to 20%

- Reduction in sludge volume up to 10%

- Reduction in Total Suspended Solids in treated influent up to 55%

- Reduction in COD in treated influent up to 30%

- Reduction of CO2 foot print of up to 15%

SMART-Plant scales-up in real environment eco-innovative and energy-efficient solutions to renovate existing wastewater treatment plants and close the circular value chain by applying low-carbon techniques to recover materials that are otherwise lost.

Seven plus two (7+2) pilot systems were optimized for more than two years in real environment in five municipal water treatment plants, including also two post-processing facilities. The systems were automatized with the aim of optimizing wastewater treatment, resource recovery, energy-efficiency and reduction of greenhouse emissions. A comprehensive SMART portfolio comprising biopolymers, cellulose, fertilizers and intermediates were recovered and processed up to the final commercializable end-products.

Dynamic modeling and superstructure framework for decision support was developed and validated to identify the optimum SMART-Plant system integration options for recovered resources and technologies.

The integration of resource recovery assets to system wide asset management programs were evaluated in each site following the resource recovery paradigm for the wastewater treatment plant of the future, enabled through SMART-Plant solutions. The project proved the feasibility of circular management of urban wastewater and environmental sustainability of the systems, through Life Cycle Assessment and Life Cycle Costing approaches as well as the global benefit of the scaled-up water solutions.

Global market deployment was achieved as right fit solution for water utilities and relevant industrial stakeholders, considering the strategic implications of the resource recovery paradigm in case of both public and private water management. New public-private partnership models were also explored connecting the water sector to the chemical industry and its downstream segments such as the construction and agricultural sector, thus generating new opportunities for funding and potential public-private competition.